Repurposing Coal-Fired Power Plants

A before and after explanation.

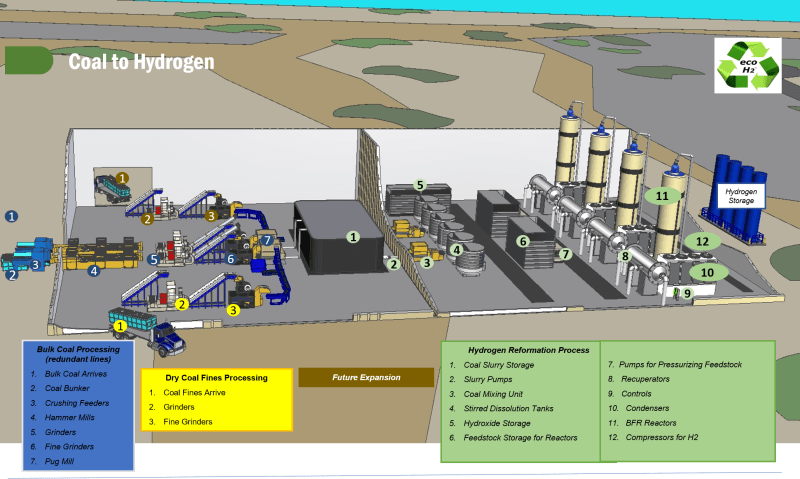

Existing coal-fired power plants have the coal infrastructure in place to bring in coal, store it, convey it to crushers, and pulverize before being injected into the boiler firebox. Learn more with this excellent tutorial on coal-fired power plant operation: How Coal-Fired Thermal Power Stations Work.

EEI plans to repurpose these coal-fired power plants.

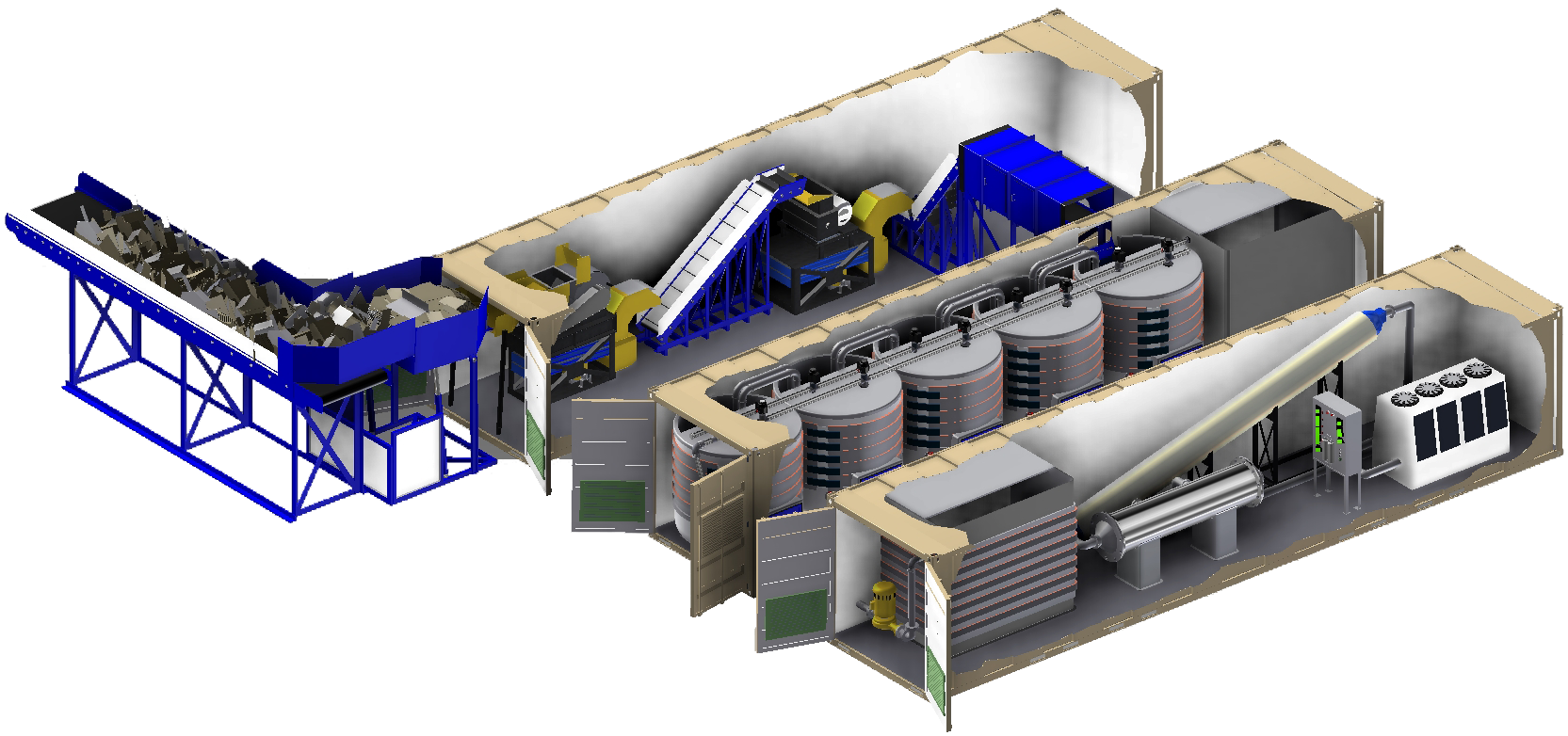

In our repurposing, we reuse almost all of the existing power plant systems in place except that instead of injecting the coal dust into the boiler, we feed that coal dust into our dissolution tanks. These tanks heat the coal dust with a caustic solution, breaking it down into a carbon-rich liquid feedstock solution.

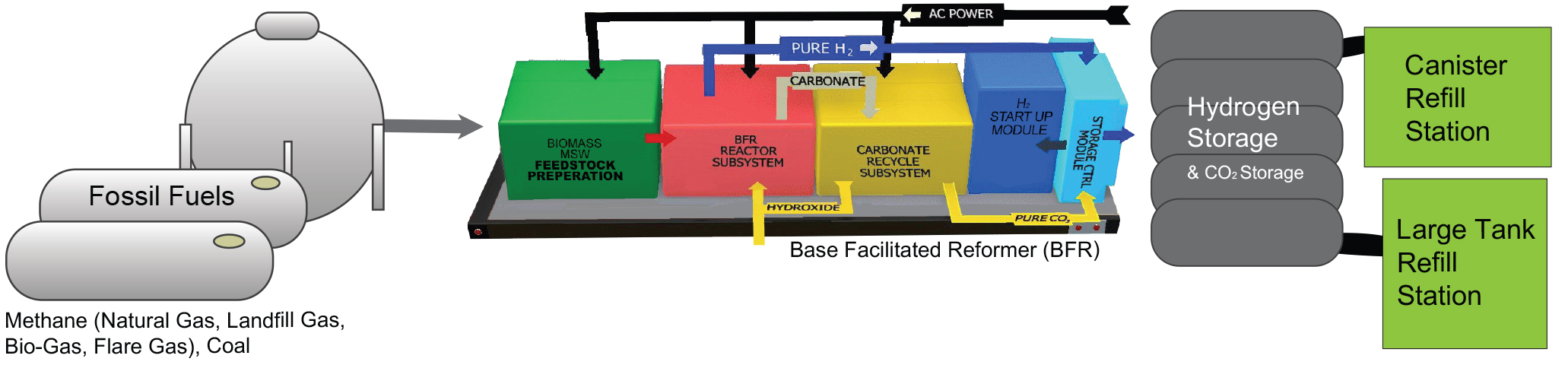

The solution goes into EEI’s patented Base Facilitated Reformer (BFR) which causes the production 98% pure hydrogen. This hydrogen gas is then fed into pressurized storage tanks, which are needed to allow for ups and downs of power demand, just like the coal piles are today. The 98% pure hydrogen does not need to be cleaned up any further like it would be for other applications like use in fuel cells because next it will be fed into H2 gas burners in the boilers. Most of the 2% impurity is methane which only further helps the combustion

Addition of MSW

In addition to the coal usage described above, EEI can combine MSW with Coal to create a higher-quality fuel source while getting rid of waste. The South African government plans to repurpose their coal-fired power plants to use hydrogen in their boilers as described above and use local MSW to supply our BFR process to produce the hydrogen

The plan is to first phase start the power plant up with pyrolysis syn gas from coal to the existing burners in the existing boilers. This pyrolysis would emit much less pollution than the direct firing of the coal. Then when the plant is up and running the BFRs can fire a new burner capable of burning hydrogen to heat the steam and finally the EEI fuel cells can cause this process to go fully electric.

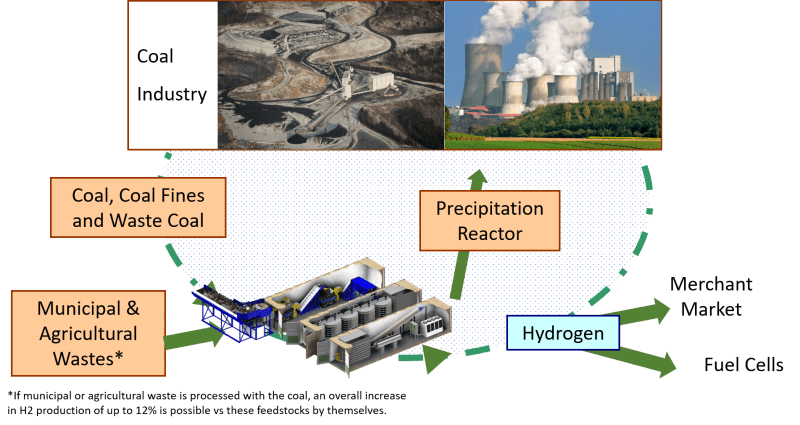

The BFR process has been demonstrated on wide variety of fuels, making it viable in multiple applications. Examples of feedstocks successfully reformed into hydrogen by BFR process include Coal Industry Waste (CIW):

- Coal

- Waste Coal

- Coal Fines

- Etc.