Base Facilitated Reformer (BFR) for Hydrogen Production

ETI’s Natural Gas Feed Stock for H2 Generation.

* 54 relevant US & International Patents

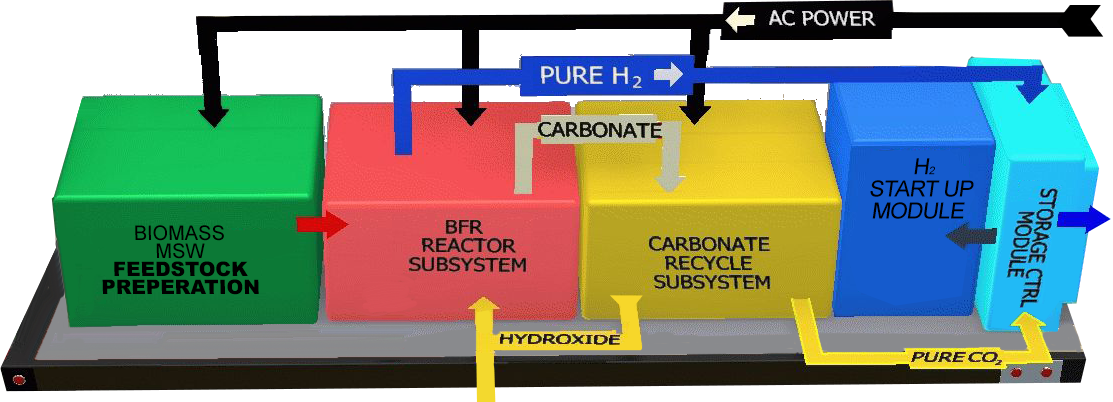

The aqueous solution in the middle of the EEI’s Bio Seperation Vessel (BSV) contains dissolved organic materials which become the feedstock to ETIs patented BFR process. This system is a low cost direct conversion of feedstocks into pure hydrogen (H2) without producing greenhouse gas as a by-product. All carbon is sequestered. Renewable feedstocks include biomass, biogas, landfill gas, methanol, ethanol, municipal solid waste and sugars. The Hydrogen produced through this process can then be stored in vessels and resold on the commercial market.

- The BFR process has been demonstrated on wide variety of fuels. A biomass reforming process towards commercialization ready for 500/1500 Kg Per Day for Ohio location demonstration.

- The reforming temperatures using the BFR process are significantly lower than the electrolysis or steam reformation process of the fuels.

- Reformation in a liquid phase at low temperatures of fuels has been demonstrated.

- The BFR process exhibits good H2 Generation rates at the low temperatures of operation.

- The BFR process is a simple one step process. Pure H2 and no CO and CO2 produced. WGS reaction and PSA are therefore avoided and the process is environmentally clean.

- The BFR process is economically feasible and competes well with other technologies.