Bio Carbon Fuels (BCF)

Feedstock Preparation for Power Generation

* Patented technologies

Lighter materials (i.e. plastics, undissolved wood, etc.) float to the surface of the solution in the BSV, where a drag chain can extract these materials. The materials are fed along conveyors into newly patented BCF Dryers which re-engineer these materials into a dry blend and granulate. The dry materials are then fed into Gasifiers creating Syngas. The SynGas is then cleaned and used to power generators, a portion of which can be used to power this entire waste reclamation facility.

The technology process is divided into three main stages:

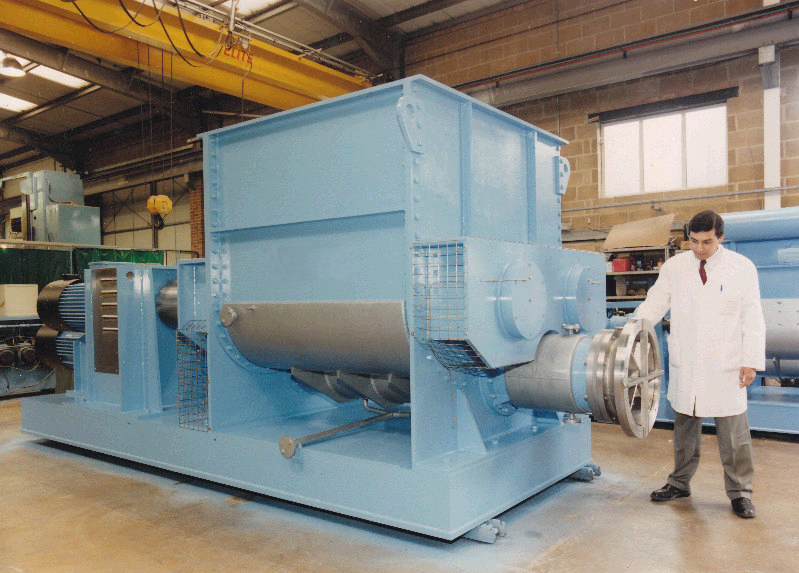

- Incoming Feedstock loaded into proprietary feedstock preparation machine, which mixes, dries, shreds and compresses the waste into solid fuel (briquettes, pellets or granules).

- The Feedstock is then fed into a pyrolysis reactor for zero emission thermal conversion of the prepared Feedstock into synthesis gas (“Syngas”)

- The resulting Syngas is then fed into a generator set to produce renewable electricity or liquefied and refined into biofuels.