Cost Effective, Eco-Friendly Municipal Solid Waste to Energy

Waste Management is Critical

Municipal Solid Waste(MSW) management is one of the world’s biggest challenges. The US currently produces over 250 million tons of MSW each year, almost 2/3 of which continues to be landfilled. Other forms of waste (wood waste, agricultural waste, industrial waste, and other solid waste) increases this quantity significantly. Worldwide, the total MSW number is 1.3 billion tons per year and projected to grow to 2.6 billion tons per year by 2025 (The Worldwatch Institute), and that number is projected to triple by 2100. The increased pressure to find alternative ways to deal with MSW will increase the catalytic forces propelling bioenergy projects forward, especially waste-to-energy projects.

- About 33% of the over 250 million tons per year of MSW in the US is recycled.

- 11% is converted to energy through old incinerators

- Over 135 million tons per year are deposited into 1,700 existing landfills, leading to immense methane emissions exceeding 1 million tons of CO2 equivalent per month.

- Many countries have governmental mandates that support our MSW to Bio-Fuel initiatives.

– EU and Brazil have landfill elimination plans

– EU, Mexico, Brazil, India, Australia & New Zealand are creating renewable energy plans - The potential market is over 1,000 projects in the US, just using MSW.

- The worldwide opportunity is almost 20 times that amount (20,000 potential projects just using MSW).

“From the Dump to the Pump”

• Bio-gases can be converted directly into hydrogen more efficiently than other disposal methods

Zero Landfill Waste

“Zero Waste is a goal that is ethical, economical, efficient and visionary, to guide people in changing their lifestyles and practices to emulate sustainable natural cycles, where all discarded materials are designed to become resources for others to use…

…Implementing Zero Waste will eliminate all discharges to land, water or air that are a threat to planetary, human, animal or plant health.”

-Zero Waste International Alliance (ZWIA)

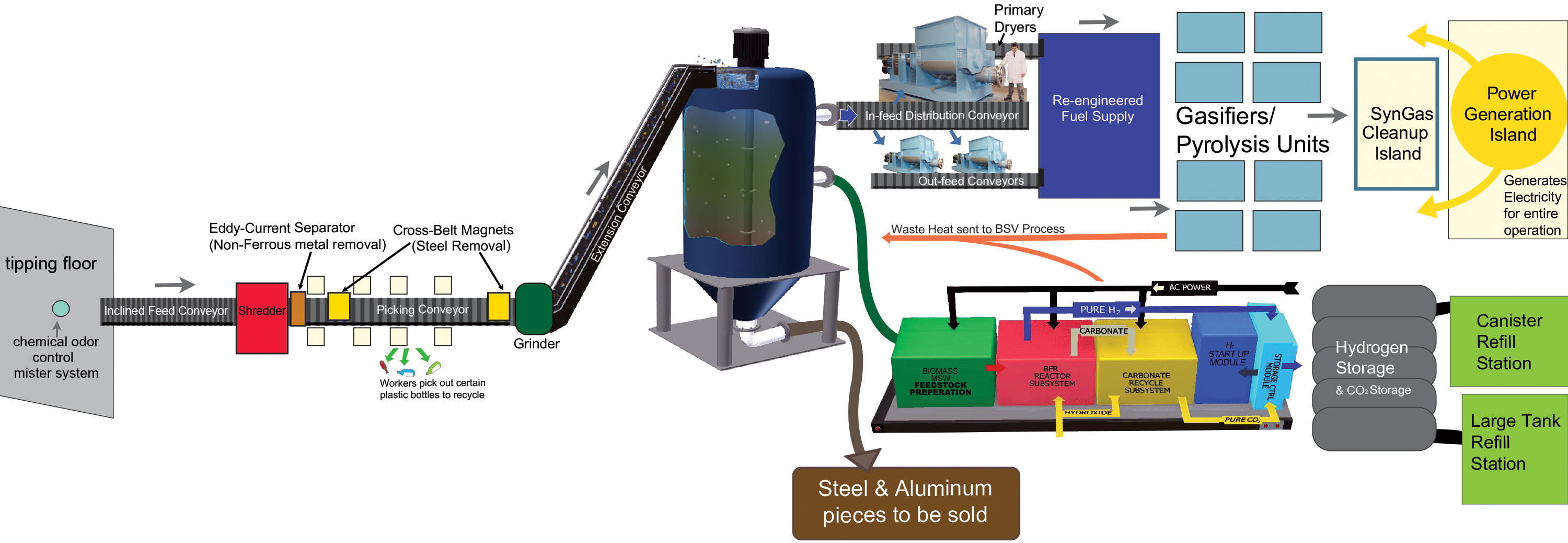

Eco Energy International (EEI) seeks to reduce landfill use while maximizing recycling and producing clean energy. EEI’s bio reformation technology extracts clean, usable Hydrogen (H2) from the organic materials in Municipal Solid Waste (MSW) while capturing their carbon content. The left over materials are then to re-engineered fuel to be the feedstock of gasifiers, creating Syngas suitable for generation of electricity or the production of additional H2. The result: instead of sending waste material to a landfill, we utilize all the materials to produce both H2 and electricity. Remaining materials are recycled and water used in this process can be reclaimed for reuse.

Solutions for Clean Energy from MSW

Bio Separation Vessel (BSV) * Patent Pending

Ground up MSW is delivered into a vessel containing a caustic solution (i.e. Caustic Soda, Caustic Potash, or Slaked Lime).

A large stirring mechanism helps dissolve organic bio-materials (i.e. paper, cardboard, wood, food waste,non-synthetic fibers/fabrics, grass clippings, etc.) into the caustic solution.

- Lighter materials from the top of the vessel are sent to BCF

- Wet caustic solution in the center of the tank is sent to BFR

- Metals at the bottom of the tank are sent to recycle

Bio Carbon Fuels (BCF) Feedstock Preparation * Patented

The technology process is divided into three main stages:

- Incoming Feedstock loaded into proprietary feedstock preparation machine, which mixes,dries, shreds and compresses the waste into solid fuel (briquettes, pellets or granules).

- The Feedstock is then fed into a pyrolysis reactor for zero emission thermal conversion of the prepared Feedstock into synthesis gas (“Syngas”)

- The resulting Syngas is then fed into a generator set to produce renewable electricity or liquefied and refined into biofuels.

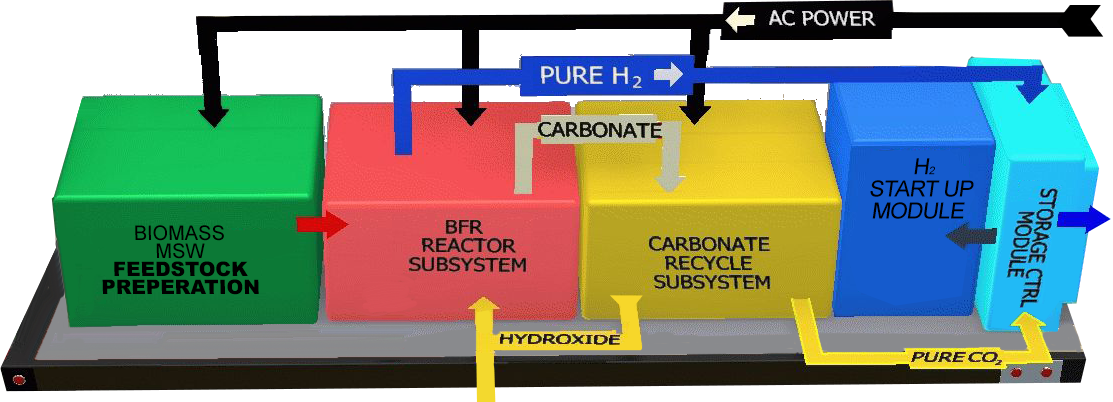

Base Facilitated Reformer (BFR) * 20 Patents

ETI’s MSW for H2 Generation!

The solution from the BSV becomes the feedstock to the patented BFR process.

This system is a low cost direct conversion of MSW into pure hydrogen (H2) without producing greenhouse gas emissions (no CO and CO2)

The H2 produced through this process is stored in vessels and delivered to existing H2 customers at below current market price.

The BFR system can utilize additional feedstocks including biomass, biogas, landfill gas, methanol, ethanol and sugars.